Long Island Flat Roof Repairs

Flat Roof Leaks Long Island

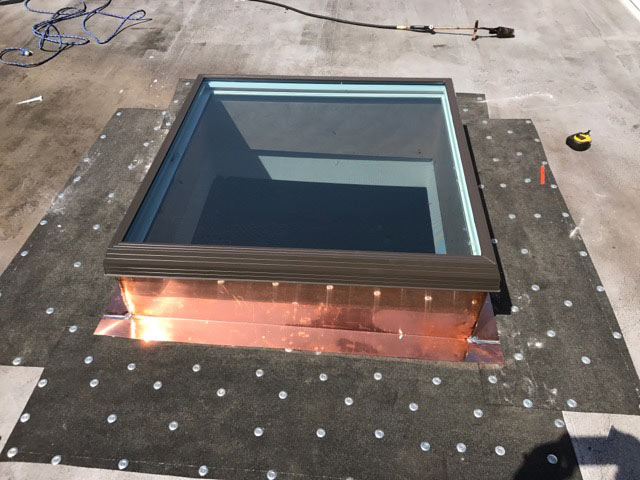

Flat roof materials last usually 15-20 years with some commercial grade applications lasting up to 30 years. Some flat roofs, however leak within 5-10 years of installation, due to openings in roof at penetrations. (vent pipes, a/c units, fence posts and perimeter flashing).

Flat Roof Repairs Long Island

Residential

Wall flashing: The most common residential flat roof leak occurs where flat roofing meets siding. The ‘flashing’ at this joint is crucial. Flashing comes in many forms. Flashing can be copper, aluminum, lead or tar. That’s right, tar. The best form of flashing with residential flat (low slope) roofing is actually none of these. Whether it is a metal or the roof sealed right to the siding, either way, it can fail. If the flat roofing were to continue up the wall behind the siding, there is no tar to fail. This method will last as long as the material. It will not fail. Physics never fails. Tricky part to this is the layers of siding. To be done properly, the flat roof (we prefer Rubber roofing) needs to continue behind all layers of siding (vinyl, insulation, asbestos and tar paper is most common).

Plumbing pipes and chimney stacks: Leaks from penetrations are easily fixed using trowel applied flashing, but Silicone based sealant with polyester fabric lasts 3-4 times as long as traditional tar-flashing.

Perimeter trim: Many roofers do not create enough overhang or the sealant they use to seal membrane to aluminum fails because it was not intended to be reliant on (1) seal that WILL FAIL. Aluminum drip edge and gutters require redundant layering of material behind and into gutter. Material on edges must be wrapped and fastened over the side, covered by aluminum edge flashing/drip edge and then fasteners patched along top edge of metal.

Failed roof seams: Failed seams can result from weather conditions during application, failed material or Poor Workmanship. TPO and Modified Bitumen roofs are our GO-TO roofing membranes for residential and commercial applications as they both utilize MOLECULAR WELDING. When trained properly (and with the help of precision Robot welders) instant bonding thru heat welding is achieved. Most residential roofers lack proper insurance and/or skill-set to install these products. High temperatures are used to WELD the material in temperatures as low as 35 degrees. Peal and Stick roofing was created for the poorly insured or non-insured roofer (sold at HOME DEPOT) but requires multiple layers to deal with the likelihood that a seam will fail and temperatures need to be 60 degree or more (to avoid using a torch). EPDM is a great material that can last 30 or more years but the seams require extensive prep work, minimum temperature requirement, air moisture affects the bond, the bonding materials have expiration and storage requirements and the set up time is variable based on many conditions, all together creating too much RISK. EPDM is however very flexible and comes in the largest sheets (as wide as 20 feet). It is black vs. TPO is white and therefore needed for aesthetics. For flexibility, small jobs and tight spaces where heat should not be used EPDM is used.

Click an image below to view gallery:

Commercial and Industrial Roof Long Island

Commercial and industrial flat roofs have perimeter issues related to gutters, coping, wall joints, issues at all penetrations and the trickiest leak – HVAC units.

Roof perimeters: Often kept inches’ shy of the edge and neatly sealed to existing or new metal using tar (and fiberglass fabric in most cases). This seal will eventually fail allowing water directly in to building or worse, in between layers of flat roofing, sometimes not noticed until roof becomes beyond repair. The adhesion between top roof and underlying roofs is vital to the top roofs survival (longevity), so avoiding leaks on a multi layered roof is vital. It is as simple as adding about 4 inches of material to the roof perimeter. This enables the roof to continue over the edge, overlapping wall or existing metal coping. This raw edge is then finished with an aluminum drip edge to fasten and cover roofing.

Failed roof seams: Failed seams can result from weather conditions during application, failed material or Poor Workmanship. In some cases, roof seams fail because the underlying roof, decking or insulation is moving. Improper fastening of deck, insulation, base sheet or dis-adhesion of underlying roof from deck can transfer stress resulting from contraction of building, causing seems to be pulled apart. Understanding the cause (not the effect) is essential in this case. Leaks from the perimeter, internal moisture (condensation) resulting from poor insulation or leaks in the building envelope need to be explored before seams are patched. More often than not the roof seams on a multiple layered Long Island low slope roof are failing because of other catalysts. TPO and Modified Bitumen roofs are our GO-TO roofing membranes for commercial applications as they both utilize MOLECULAR WELDING. When trained properly (and with the help of precision Robot welders) instant bonding thru heat welding is achieved. EPDM is a great material that can last 30 or more years but the seams require extensive prep work, minimum temperature requirement, air moisture affects the bond, the bonding materials have expiration and storage requirements and the set up time is variable based on many conditions, all together creating too much RISK. EPDM is however very flexible and comes in the largest sheets (as wide as 20 feet). It is black vs. TPO is white and therefore needed for aesthetics. For flexibility, small jobs and tight spaces where heat should not be used EPDM is used.

Other Common Roof Leak Situations on Long Island

Click the links below to read about other common leaks that can affect your home.

Warning: Undefined variable $post in /home/lms2012/public_html/leakstoppersinc.com/wp-content/themes/leakstoppers/functions.php on line 82

- Long Island Attic Leak Repairs

- Long Island Chimney Leak Repairs

- Long Island Ice Dam Removal & Damage Repair

- Long Island Negative Air Repairs

- Long Island Siding Leak Repairs

- Long Island Skylight Leak Repairs

- Long Island Valley Leak Repairs

- Long Island Vent Pipe Leak Repairs

- Long Island Window Leak Repairs